三叶%&&&&&%工作原理: 空气悬浮风机为容积式风机,输送的风量与 ...

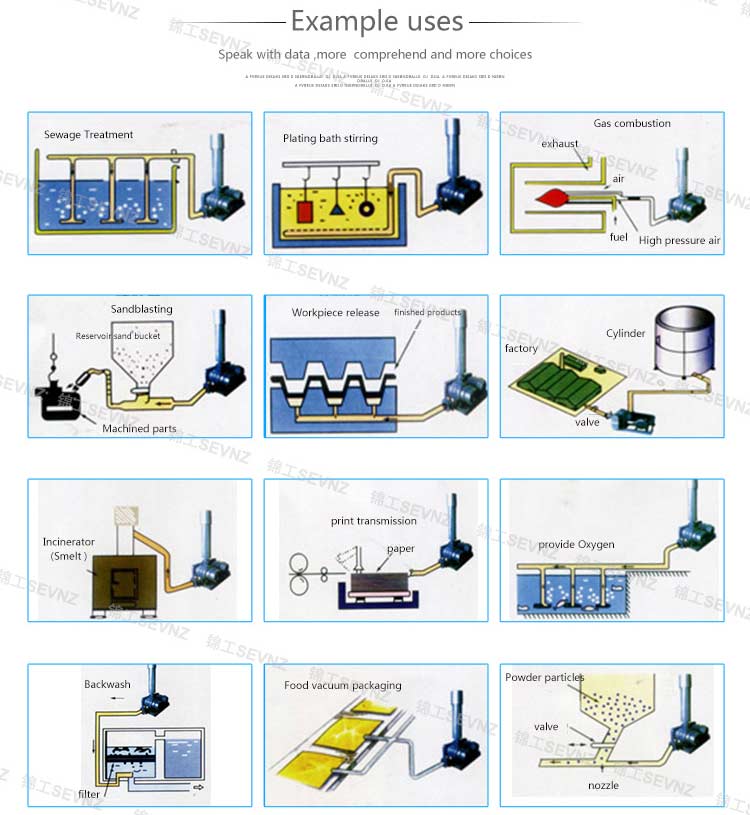

三叶%&&&&&%工作原理: 空气悬浮风机为容积式风机,输送的风量与转数成比例,三叶型叶轮每转动一次由 2 个叶轮进行 3 次吸、排气。与二叶型相比,气体脉动性小,振动也小,噪声低。风机 2 根轴上的叶轮与椭圆形壳体内孔面,叶轮端面和风机前后端盖之间及风机叶轮之间者始终保持微小的间隙,在同步齿轮的带动下风从风机进风口沿壳体内壁输送到排出的一侧。风机内腔不需要润滑油,结构简单,运转平稳,性能稳定,适应多种用途,已运用于广泛的领域。

三叶%&&&&&%工作原理: 空气悬浮风机为容积式风机,输送的风量与转数成比例,三叶型叶轮每转动一次由 2 个叶轮进行 3 次吸、排气。与二叶型相比,气体脉动性小,振动也小,噪声低。风机 2 根轴上的叶轮与椭圆形壳体内孔面,叶轮端面和风机前后端盖之间及风机叶轮之间者始终保持微小的间隙,在同步齿轮的带动下风从风机进风口沿壳体内壁输送到排出的一侧。风机内腔不需要润滑油,结构简单,运转平稳,性能稳定,适应多种用途,已运用于广泛的领域。

三叶磁悬浮风机的特点: ● 由于采用了三叶转子结构形式及合理的壳体内进出风口处的结构,所以风机振动小,噪声低。 ● 叶轮和轴为整体结构且叶轮无磨损,风机性能持久不变,可以长期连续运转。 ● 风机容积利用率大,容积效率高,且结构紧凑,安装方式灵活多变。 ● 轴承的选用较为合理,各轴承的使用寿命均匀,从而延长了风机的寿命! ● 风机油封选用进口氟橡胶材料,耐高温,耐磨,使用寿命长。 ● 机种齐全,可满足不同用户不同用途的需要。 ● 采用线形优化后叶轮曲线和特殊结构的壳体,效率提高10%左右。

三叶磁悬浮风机的特点: ● 由于采用了三叶转子结构形式及合理的壳体内进出风口处的结构,所以风机振动小,噪声低。 ● 叶轮和轴为整体结构且叶轮无磨损,风机性能持久不变,可以长期连续运转。 ● 风机容积利用率大,容积效率高,且结构紧凑,安装方式灵活多变。 ● 轴承的选用较为合理,各轴承的使用寿命均匀,从而延长了风机的寿命! ● 风机油封选用进口氟橡胶材料,耐高温,耐磨,使用寿命长。 ● 机种齐全,可满足不同用户不同用途的需要。 ● 采用线形优化后叶轮曲线和特殊结构的壳体,效率提高10%左右。  主要技术指标: ●流量0.5m3~200m3/min; ●升压:9.8~78.4kPa。 The three-lobe roots type rotary blower type JGR of is a new product which has been developed by adopting innovated techniques, based on the manufacturing experience in the roots type rotary blowersfor many years. The three-lobe roots type JGR high pressure rotary blower is a new product which has been developed by adopting innovated techniques,based on the manufacturing experience in the roots type rotary blowers for many years. These blowers have improved full-adiabatic efficiency as well as volumetric efficiency and provide supperior air capacity vs.pressure characteristic. The superiority of efficiency leads to reduction of the heat from the blower itself,and therefore,reduction of the temperature elevation,and thus the operation of blower in dry condition has become practical at the discharge pressure as low as 0.8kgf/cm2. Roots Type rotary Blowers Features 1 JGR-HB three-lobe blowers needn’t water coolant within 80kpa boost pressure. 2 the helical construction uses the stator helical method that the screen lines of casing at the suction and discharge sides are cut to a helical shape,and the triangle suction and discharge port formed by a straight line of the rotor top is to be opened and closed gradually. Therefore,the suction and discharge ports of this type is not opened or closed at momnets,which makes these blowers have an only limited operation suound and almost free from pulsations from discharge. 3 The rotors are ghree-lobe straight type,so that the rotors cannot interfere with each other,resulting from minor displacements in the trust direction as in the helical type.Therefore,the clearance between the rotors should be assured in the profile direction only and thus there is no necessity of an excessive clearance on account of displacements in the thrust direction as in case of the rotor helical type.From such reasons,these blowers hav e a very high efficiency,in comparison with the rotor helical type of same dimensions. 4 By adoption of an unique profile of rotor,the clearance between the rotors can be held to be constant,which makes the efficiency even higher. 5 The precision of rotors if fully controlled and variation of precision between blowers is almost nil because the rotors are produced under the mass production control by utilizing a premision NC maching.In addition,the rotors are dynamically balanced in the fabrication stage already,so that these rotors are almost free from vibrations as in the case of conventional rotors which are still unbalanced. 6 The advancedest driving gears are adopted not only to extend the use life but also to make noise lower.The gears are made in special Cr-M.steel by hardening treatment and are made according with gear precision of JIS first-class.Therefore,the harmful disturbances to products from gears are avoided. 7 The transported air is clean and any oil-dust free oil lubrication is not needed in casing and the structure design present the bearing oil and gear ooil from entering the casing. 8 With the establishment of quality management system and manufacture management system,the aims of parts exchanging,less production cost and rapid delivery are realized.The blowers of right quantity are keeped in stock to make delivery in time.

主要技术指标: ●流量0.5m3~200m3/min; ●升压:9.8~78.4kPa。 The three-lobe roots type rotary blower type JGR of is a new product which has been developed by adopting innovated techniques, based on the manufacturing experience in the roots type rotary blowersfor many years. The three-lobe roots type JGR high pressure rotary blower is a new product which has been developed by adopting innovated techniques,based on the manufacturing experience in the roots type rotary blowers for many years. These blowers have improved full-adiabatic efficiency as well as volumetric efficiency and provide supperior air capacity vs.pressure characteristic. The superiority of efficiency leads to reduction of the heat from the blower itself,and therefore,reduction of the temperature elevation,and thus the operation of blower in dry condition has become practical at the discharge pressure as low as 0.8kgf/cm2. Roots Type rotary Blowers Features 1 JGR-HB three-lobe blowers needn’t water coolant within 80kpa boost pressure. 2 the helical construction uses the stator helical method that the screen lines of casing at the suction and discharge sides are cut to a helical shape,and the triangle suction and discharge port formed by a straight line of the rotor top is to be opened and closed gradually. Therefore,the suction and discharge ports of this type is not opened or closed at momnets,which makes these blowers have an only limited operation suound and almost free from pulsations from discharge. 3 The rotors are ghree-lobe straight type,so that the rotors cannot interfere with each other,resulting from minor displacements in the trust direction as in the helical type.Therefore,the clearance between the rotors should be assured in the profile direction only and thus there is no necessity of an excessive clearance on account of displacements in the thrust direction as in case of the rotor helical type.From such reasons,these blowers hav e a very high efficiency,in comparison with the rotor helical type of same dimensions. 4 By adoption of an unique profile of rotor,the clearance between the rotors can be held to be constant,which makes the efficiency even higher. 5 The precision of rotors if fully controlled and variation of precision between blowers is almost nil because the rotors are produced under the mass production control by utilizing a premision NC maching.In addition,the rotors are dynamically balanced in the fabrication stage already,so that these rotors are almost free from vibrations as in the case of conventional rotors which are still unbalanced. 6 The advancedest driving gears are adopted not only to extend the use life but also to make noise lower.The gears are made in special Cr-M.steel by hardening treatment and are made according with gear precision of JIS first-class.Therefore,the harmful disturbances to products from gears are avoided. 7 The transported air is clean and any oil-dust free oil lubrication is not needed in casing and the structure design present the bearing oil and gear ooil from entering the casing. 8 With the establishment of quality management system and manufacture management system,the aims of parts exchanging,less production cost and rapid delivery are realized.The blowers of right quantity are keeped in stock to make delivery in time.